stock.picking odoo

A Deep Dive into Stock.Picking in Odoo

Stock.picking is a fundamental object in Odoo's inventory management system. Understanding how to effectively utilize stock.picking within Odoo is crucial for seamless order fulfillment and inventory tracking. This article delves into the intricacies of stock.picking odoo, providing practical guidance and answers to common questions.

What is a Stock.Picking in Odoo?

A stock.picking in Odoo represents a physical movement of goods. Think of it as the concrete embodiment of a sale order or purchase order—the physical act of taking goods from a location to another location within the Odoo warehouse management system (WMS). This crucial step in the entire Odoo stock.picking process ensures the movement of items accurately reflected in your Odoo inventory.

How Stock.Pickings relate to Orders

stock.picking odoo directly links to sales orders and purchase orders. A sales order triggers the creation of a sales stock.picking, while a purchase order necessitates a purchase stock.picking. Understanding these relationships is vital for managing your warehouse and tracking stock accurately. Every movement you make concerning goods and your stock.picking process needs to be mapped accordingly in the system to correctly match your goods. Your Odoo stock.picking records are also valuable information when investigating issues. stock.picking odoo plays a key role in this matching and record-keeping process.

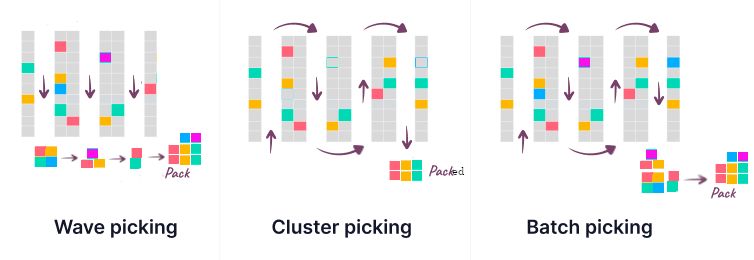

Different Types of Stock.Picking in Odoo

Source: odooexperts.nl

While many stock.picking odoo movements have similarities, the system differentiates between various types, each with unique triggers and operations. Common types include:

-

Internal Transfers: These stock.picking odoo processes move goods between different locations within your warehouse.

-

Sales Orders: stock.picking odoo created to fulfill sales orders from customers. These movements are carefully tracked.

-

Purchase Orders: These are vital purchase stock.picking odoo operations related to receiving goods from suppliers.

Creating a New Stock.Picking Odoo

Source: aktivsoftware.com

To initiate a stock.picking in Odoo:

Manually Generating a Stock.Picking Odoo from Sales Orders:

- Go to the sales order record you need to fulfill in Odoo.

- Identify the appropriate sales stock.picking record in Odoo.

- Click on the

Pickingtab. - If appropriate, adjust stock quantity or manually enter relevant fields concerning stock.picking.

- Generate and finalize stock.picking odoo record to commence the goods shipment in Odoo.

Automatically Creating a Stock.Picking Odoo:

Sometimes Odoo handles stock.picking odoo automatic assignments (e.g. using workflow rules or triggers) for certain operations. Odoo often auto-creates stock.picking to handle situations as straightforward as these!

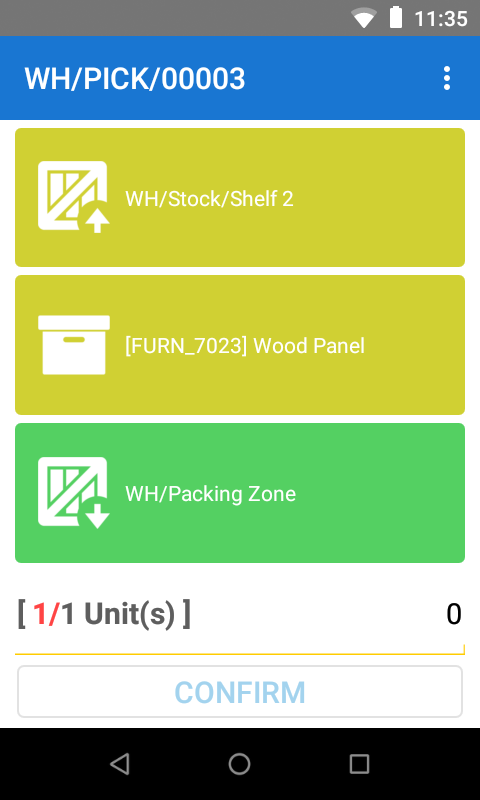

Updating Stock.Picking Odoo Status

Source: webkul.com

As you're managing your Odoo stock.picking, statuses (e.g., "draft", "assigned", "in progress") allow you to track the stages your stock.picking odoo goes through. These status transitions help in managing tasks and preventing errors in inventory. Stock.Picking in Odoo keeps careful watch over these changes. Your workflow with your Odoo stock.picking process is improved through understanding these transitions and their related functions.

Source: ventor.tech

Managing Stock.Picking Lines

Each stock.picking odoo often comprises lines. Stock.picking line creation in Odoo gives structure to each order and facilitates effective organization for multiple products in the order. Each stock.picking line specifies product quantities to help fulfill an order, and their stock.picking process. You can update the quantity on any particular stock.picking line when required.

Printing Stock.Picking Labels

Odoo stock.picking functionality has tools to prepare labels and documentation like waybills required for each fulfillment. Odoo's stock.picking process assists in automating much of this labeling functionality. This improves logistics for stock.picking odoo activities, and avoids many human errors with documents and processes.

Common Stock.Picking Odoo Errors and Solutions

Many errors are associated with stock.picking odoo tasks. Ensure all pertinent stock locations and other key factors within stock.picking processes in Odoo are accurate. Stock.Picking accuracy is vital, since discrepancies in stock.picking records can create large issues for your company's financial performance!

Troubleshooting Stock.Picking:

- Incorrect Quantities: Double-check the quantities specified for your stock.picking lines, checking stock available against orders. Make sure the assigned stock units in your warehouse match up with your order and related processes, checking the stock.picking odoo records frequently for best accuracy.

- Missing Products: Confirm products included in the order accurately exist for your stock.picking order fulfillment in Odoo, referencing product codes. Incorrect codes can cause discrepancies between inventory stock and picking in Odoo processes.

- Discrepancies: If numbers seem wrong on the assigned pickings or on shipments or on returns of stock.picking orders in Odoo, identify what information is off for an appropriate resolution of any stock discrepancy.

Odoo Stock.Picking and Inventory Management

Your stock.picking procedures are deeply integrated with Odoo's inventory management. Efficient processes and effective solutions for inventory, order and stock.picking management are directly linked to good warehouse organization. Inventory records are linked directly to all relevant aspects of your stock.picking workflows and process.

Stock.Picking Odoo and Reporting

Reporting in Odoo offers crucial data insights for assessing your stock.picking odoo process performance. Track key metrics like order fulfillment rates, and identify trends affecting efficiency of processes linked with stock.picking Odoo functionality.

stock.picking odoo efficiency is crucial in your warehouse environment. Accurate stock data is essential. Understanding and executing accurate stock.picking methods in Odoo significantly impacts financial stability and operational processes.