stock picking ladders for warehouses

Stock Picking Ladders for Warehouses: A Comprehensive Guide

Warehouses, bustling centers of activity, rely heavily on efficient stock picking. Efficient and safe access to various storage levels is crucial, and stock picking ladders for warehouses play a pivotal role. This guide will delve into the world of these essential tools, exploring their various types, crucial safety considerations, and proper usage techniques. Stock picking ladders for warehouses are essential equipment, ensuring both productivity and personnel safety.

Choosing the Right Stock Picking Ladder for Your Warehouse

3.1 Understanding Your Specific Needs

Selecting the correct stock picking ladders for warehouses is paramount. Factors like warehouse layout, storage height, frequency of use, and the type of goods being picked significantly impact your choice. Consider the various stock picking ladders for warehouses available to determine the best solution.

3.2 Types of Stock Picking Ladders

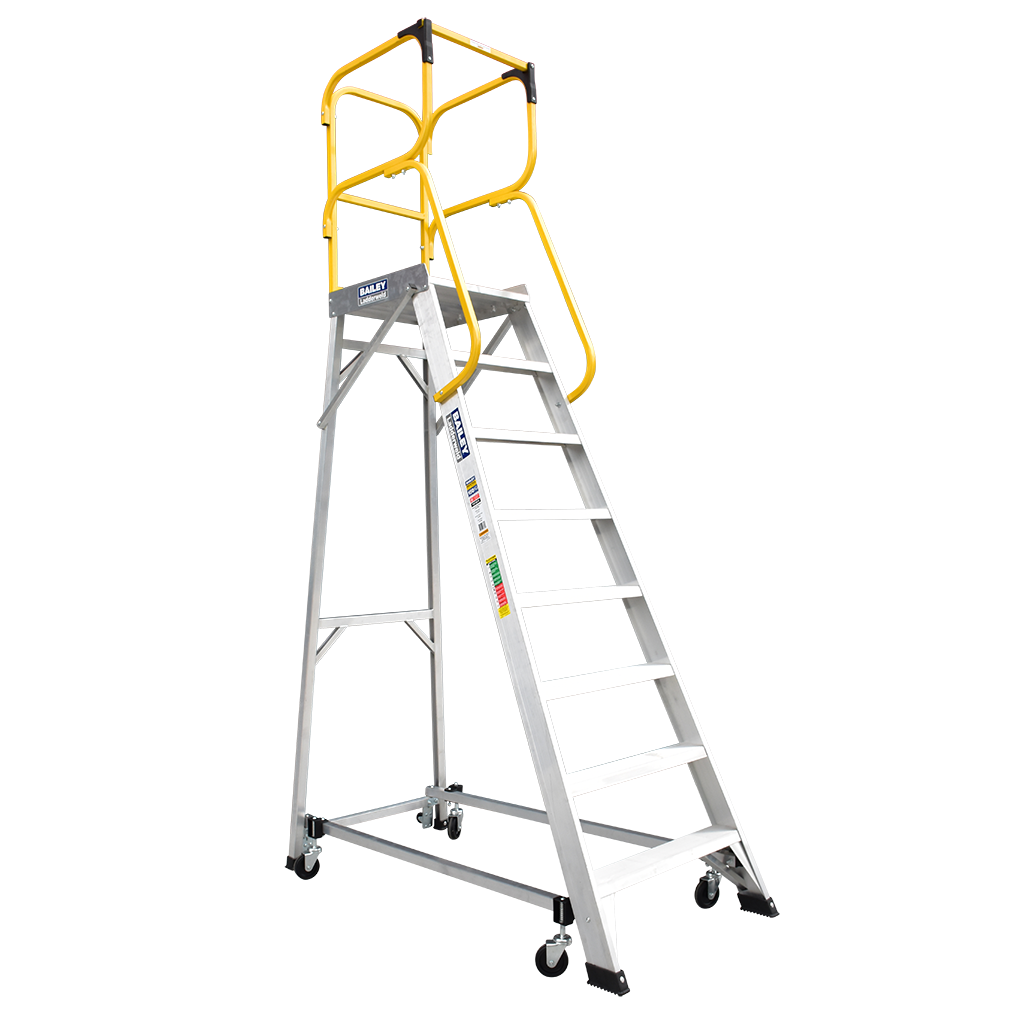

Various stock picking ladders for warehouses cater to distinct needs. Some options include:

- Standard Fixed Ladders: A cost-effective choice for smaller warehouses or low-height racking systems. Stock picking ladders for warehouses such as these often provide excellent value. But check if your safety regulations allow standard fixed ladders in high-traffic areas in the warehouse;

- Articulating Ladders: Flexible in their positioning and range, stock picking ladders for warehouses of this type provide wide reaching potential and excellent visibility. They are an exceptional choice for versatile access and efficient stock picking ladders for warehouses. These may sometimes offer advantages over standard fixed stock picking ladders for warehouses;

- Aluminum Extension Ladders: Great for mid-range stock picking. Stock picking ladders for warehouses made of lightweight aluminum offer improved ergonomics during extended work. Durability and maneuverability of aluminum stock picking ladders for warehouses are some of their advantages;

- Telescopic Ladders: Offering adjustable height and ease of transport; this category of stock picking ladders for warehouses might be preferable to fixed stock picking ladders for warehouses when frequent adjustments of picking height are necessary. This also increases storage accessibility via stock picking ladders for warehouses.

Choosing the suitable stock picking ladders for warehouses greatly affects warehouse efficiency; choosing incorrectly can impact productivity.

Safety Considerations for Stock Picking Ladders in Warehouses

4.1 Regular Maintenance and Inspections

Regular inspection of stock picking ladders for warehouses is paramount. Check for loose parts, damage, or deterioration. Ensure compliance with the warehouse safety regulations for appropriate maintenance intervals of the stock picking ladders for warehouses. Stock picking ladders for warehouses should always be in excellent condition.

4.2 Proper Positioning and Stability

The stability of stock picking ladders for warehouses significantly impacts safety. Never lean a stock picking ladder for warehouses against unstable objects; select a secure base. Adequate anchoring to stabilize a stock picking ladder for warehouses during use can increase safety while enhancing the efficiency of stock picking ladders for warehouses on your worksite.

4.3 Load Capacity and User Training

Stock picking ladders for warehouses always have load limits. Exceeding these limits poses severe safety hazards. Carefully inspect and utilize the appropriate stock picking ladder for warehouses, following the manufacturer's recommendations regarding weight capacity for reliable usage. Thorough training in the correct procedures to assemble and deploy the stock picking ladder for warehouses will ensure safe practice among your staff using these crucial warehouse tools. Rigorous adherence to this factor reduces warehouse accidents from unsafe handling and usage of stock picking ladders for warehouses. Consistent, robust stock picking ladders for warehouses safety regulations should be strictly enforced.

How to Use Stock Picking Ladders for Warehouses Safely

5.1 Proper Setup and Anchoring

- Place stock picking ladders for warehouses on a level and firm surface for support, maintaining balance; a sturdy platform must be available and sufficient to handle a heavy-duty stock picking ladder for warehouses. The appropriate placement and proper maintenance of a stock picking ladder for warehouses is integral to a safe workflow.

- Secure the stock picking ladders for warehouses with additional supports where needed. Appropriate safety harnesses are also key for securing warehouse personnel when working with a stock picking ladder for warehouses. These steps dramatically elevate workplace safety by leveraging effective solutions for safe use of stock picking ladders for warehouses.

- Stock picking ladders for warehouses that are positioned appropriately maintain adequate support and can therefore limit risks involved during assembly and storage; their effectiveness when properly positioned and anchored leads to a more robust warehousing operation.

5.2 Safe Climbing Practices

- Ensure your uniform adheres well and does not impede your climbing or impede the safe assembly or placement of your stock picking ladder for warehouses. Wear sturdy footwear while using stock picking ladders for warehouses; improper shoes could affect safety and workplace efficiency.

- One at a time, use a stock picking ladder for warehouses when navigating storage or when ascending or descending, especially in tight warehouse conditions.

- Keep a safe distance from moving machinery and hazards; a well-balanced plan helps you utilize your stock picking ladders for warehouses in accordance with safety policies in warehouses.

Stock Picking Ladder Maintenance Schedule and Replacement Guidelines

Source: com.sg

Develop a robust stock picking ladder for warehouses maintenance checklist. The checklist should outline procedures for inspections, cleaning, and minor repairs for each type of stock picking ladder for warehouses. Ensuring that each of these tasks are effectively carried out minimizes the risks associated with improperly maintained stock picking ladders for warehouses while helping warehouses maintain compliance and avoid potentially hazardous issues in stock picking operations, significantly reducing risk of work site injuries, loss of stock, or disruption.

6.2 Determining When to Replace a Stock Picking Ladder

Regular inspection of your stock picking ladders for warehouses is essential, checking for damage and deterioration to determine whether replacements are required. Worn components, particularly hinges and the supports for stock picking ladders for warehouses, signify a necessity to promptly replace parts and prevent workplace accidents from material-related failure in the structure of your stock picking ladder for warehouses. The reliability and durability of a properly maintained and inspected stock picking ladder for warehouses significantly minimizes work site injuries and disruptions from poor structural components.

Compliance with Safety Standards for Stock Picking Ladders

7.1 Relevant OSHA Regulations

Review current Occupational Safety and Health Administration (OSHA) guidelines on ladder safety. These are integral regulations concerning stock picking ladders for warehouses; these can also determine specifications, safe setup, or inspection needs of a particular stock picking ladder for warehouses. This step further guarantees compliance while improving worker safety standards concerning the various models and types of stock picking ladders for warehouses. This ensures adherence to safety procedures in your stock picking ladders for warehouses. Stock picking ladders for warehouses and adhering to OSHA regulations goes hand in hand to prevent injuries and liabilities at the work site.

7.2 Importance of Documentation

Maintain proper records regarding your stock picking ladders for warehouses including maintenance schedules, inspections, and repairs to uphold safety and traceability. Keeping diligent records is an integral component for your warehouse operations and safe practice, ensuring efficient stock picking ladders for warehouses in line with standards of compliance. The systematic documentation of all facets, such as parts replacement, maintenance schedules, and stock picking ladders for warehouses specific tasks will elevate worker safety standards.

Source: egaproducts.com

Integrating Stock Picking Ladders into Your Warehouse Workflow

8.1 Streamlining Pick and Placement Procedures

Enhance picking and placement processes by efficiently coordinating the usage of your stock picking ladders for warehouses in different parts of your facility. Strategical planning can improve operational productivity using appropriate stock picking ladders for warehouses. This can improve timeliness during pick and pack processes, optimize stock picking ladders for warehouses utilization and streamline workflow for heightened warehouse efficiency; optimized usage greatly impacts output when correctly implementing stock picking ladders for warehouses for inventory movement in a specific workspace.

8.2 Ergonomic Considerations in Using Stock Picking Ladders

Acknowledge ergonomic aspects related to your employees when implementing stock picking ladders for warehouses. Ergonomic workplace procedures for optimal workflow reduce work fatigue among staff when operating stock picking ladders for warehouses. Proper procedures and techniques also prevent accidental injury with safe implementation of stock picking ladders for warehouses.

Budget Considerations for Stock Picking Ladders

9.1 Cost-Effectiveness Analysis

Conduct thorough research before procuring any stock picking ladders for warehouses. This allows a deep-dive comparison of multiple stock picking ladders for warehouses providers in terms of budget, quality, and features of stock picking ladders for warehouses. Identify and leverage deals; these deals and considerations allow a more holistic comparison of stock picking ladders for warehouses.

9.2 Optimizing Your Investment

Strategic investments with efficient solutions lead to long-term financial savings. Appropriate budgeting is essential for stock picking ladders for warehouses to effectively maximize warehouse space while complying with industry standards. This allows effective stock management via suitable solutions provided by suitable models and specifications in stock picking ladders for warehouses.

Addressing Potential Issues with Stock Picking Ladders in Warehouses

Source: egaproducts.com

10.1 Addressing Ladder Maintenance Issues

Thorough inspections and quick troubleshooting in response to maintenance problems on stock picking ladders for warehouses contribute significantly to operational efficiency by ensuring continued and consistent use. Maintenance needs should be handled promptly for the safe and efficient operation of the stock picking ladders for warehouses you are currently using, as appropriate safety practices will avoid costly problems down the line if preventative maintenance measures are not practiced and undertaken.

10.2 Implementing Strategies for Incident Response

Source: co.uk

Develop emergency protocols that quickly respond to accidents involving stock picking ladders for warehouses. Ensure these procedures for responding to injuries from accidents with stock picking ladders for warehouses are in line with legal requirements and industry best practices to safeguard workers from further injury.

Conclusion

Proper use and maintenance of stock picking ladders for warehouses are crucial elements that safeguard employee well-being, optimize workflow, and enhance efficiency, supporting overall success for a warehousing business; selecting the appropriate models for your environment is a cornerstone of productivity when utilizing stock picking ladders for warehouses in your facilities. Efficient selection, consistent inspection, and appropriate utilization of these tools are a sure path towards smooth operations. A stock picking ladder for warehouses, carefully selected and strategically deployed in line with a detailed checklist of essential operational guidelines, paves the path to efficient warehouse operations, all stemming from meticulous and effective strategies concerning the usage of your stock picking ladders for warehouses. A carefully considered and well-established system in managing your stock picking ladders for warehouses will enhance all business procedures with a consistent emphasis on safe stock picking practices. Choosing the right stock picking ladders for warehouses that accurately reflect your specific operational and safety requirements enhances the operational and safety aspects of your warehouse procedures. Correct implementation of proper maintenance schedules enhances the productivity of stock picking ladders for warehouses within your operational setting.