stock picking carts

Stock Picking Carts: Streamlining Your Warehouse Operations

Stock picking carts are essential tools for warehouses and distribution centers. These mobile platforms, designed to optimize picking processes, can significantly improve efficiency, reduce errors, and minimize wasted time. This comprehensive guide dives deep into the world of stock picking carts, offering insights, how-to instructions, and a breakdown of various features and functionalities. Mastering the use of stock picking carts will revolutionize your inventory management strategies.

Understanding Stock Picking Carts

What are Stock Picking Carts?

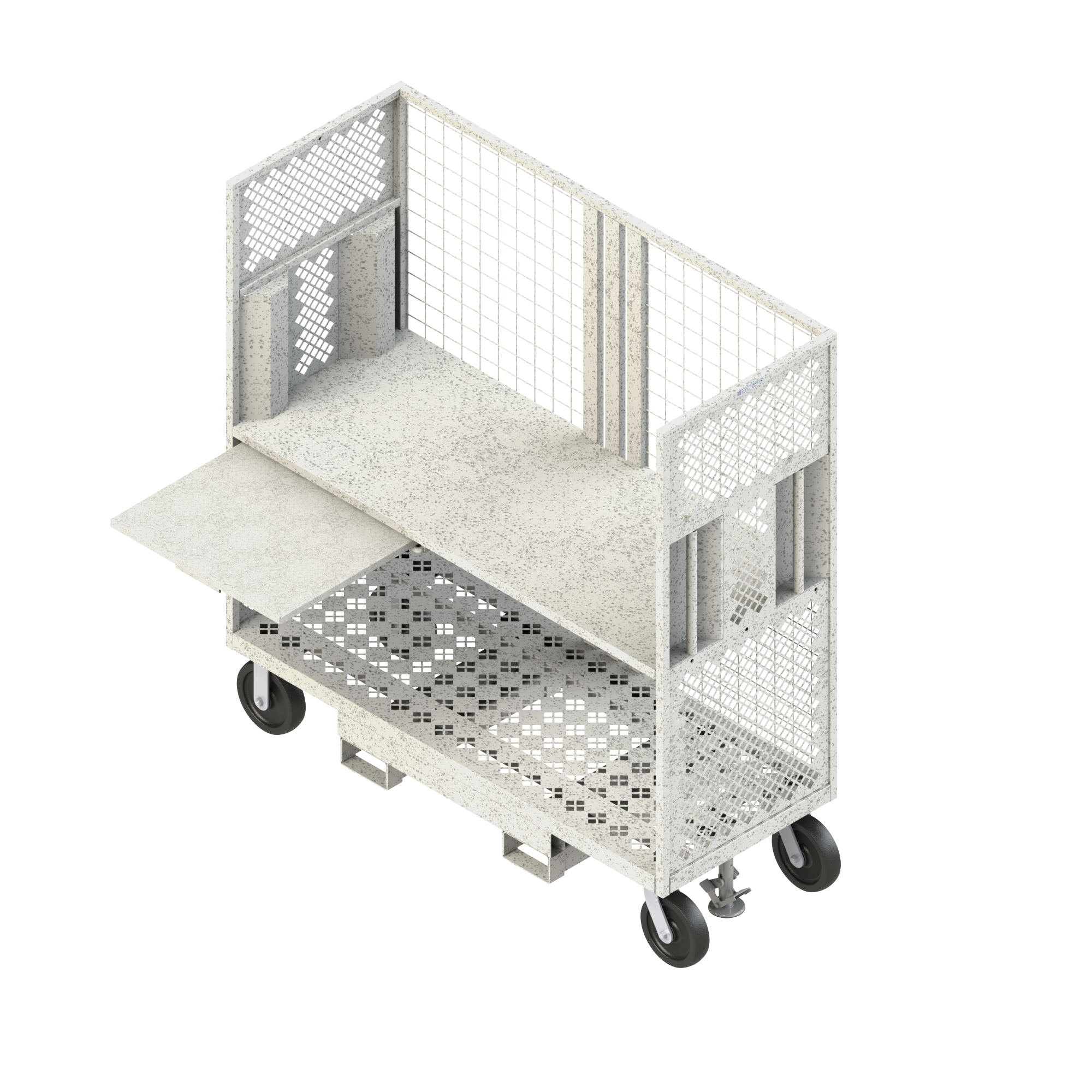

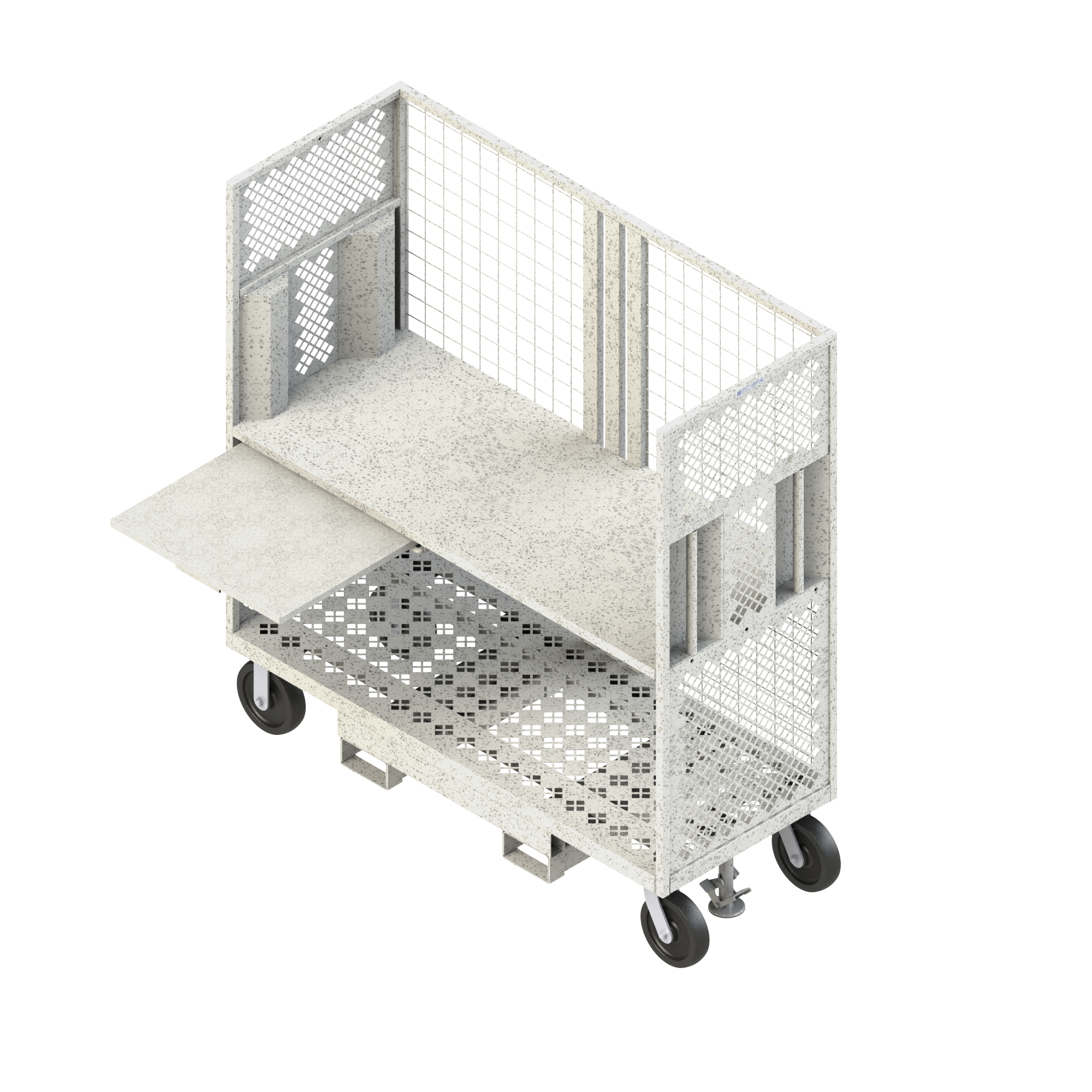

Source: nationalcart.com

Stock picking carts, often referred to as picking carts or stock carts, are mobile platforms equipped with storage capabilities. They're specifically designed to aid employees in efficiently locating, retrieving, and transporting stock within a warehouse environment. Different types of stock picking carts accommodate varying inventory needs, making them adaptable for various operational setups. Understanding the nuances of stock picking carts and their potential benefits will ultimately shape warehouse strategy and optimize productivity.

Key Features of Effective Stock Picking Carts

Effective stock picking carts often incorporate several features to optimize warehouse operations. These features could include adjustable shelving or racks, various compartmentalization, built-in barcode scanners, or integrated weight scales for better accuracy. Proper assessment of required functionalities is paramount when investing in stock picking carts. Each stock picking cart choice reflects the demands and complexities of the warehouse layout and stock picking routines.

Source: bigcommerce.com

The Impact on Warehouse Productivity with Stock Picking Carts

The implementation of well-designed stock picking carts can dramatically improve the pace and precision of order fulfillment in any warehouse or fulfillment center. Streamlining the process significantly impacts worker satisfaction, reducing fatigue and errors while optimizing your return on investment with effective stock picking carts. Efficient stock picking carts lead to increased throughput, ultimately yielding significant financial gains. This focus on efficient stock picking carts highlights their core role in modern warehousing and distribution.

How to Choose the Right Stock Picking Cart

Considering Different Types of Stock Picking Carts

There's a plethora of stock picking cart types available, each with unique attributes. The best choice depends heavily on your specific requirements. Manual stock picking carts offer a basic yet practical solution, while electric stock picking carts enhance productivity. Automated systems for high-volume operations represent advanced solutions. Your warehouse operations should influence the precise type of stock picking cart to deploy. Stock picking cart technology has rapidly advanced to suit diverse inventory conditions.

Matching Carts to Your Warehouse Layout

A crucial aspect of successful implementation is tailoring the stock picking carts to your warehouse's design and inventory arrangement. An adaptable stock picking cart can address different areas and workflows effectively, improving inventory processes and overall performance. Proper sizing and capacity alignment with the warehouse layout directly impacts the functionality and usability of stock picking carts, enhancing the inventory management process. Different layouts and stock organization necessitate evaluating varying models of stock picking carts to guarantee optimum performance.

Budget Considerations and Return on Investment (ROI) with Stock Picking Carts

Investment in stock picking carts often involves substantial upfront costs. Therefore, a detailed ROI analysis is recommended. By examining labor costs reduction and faster picking cycles using stock picking carts, companies can predict how investment impacts overall warehouse output, effectively estimating its return on investment with optimized stock picking carts. Weighing potential gains against financial commitment, firms can calculate a precise estimate of potential gains associated with acquiring new stock picking carts. Understanding cost projections helps streamline budgetary plans surrounding this valuable resource of stock picking carts.

How-to Guide for Stock Picking Carts

Setup and Training Procedures for Stock Picking Carts

Proper stock picking cart implementation goes beyond acquiring the equipment. Rigorous setup protocols and comprehensive training programs for employees are paramount. A streamlined procedure enhances productivity, reduces errors, and provides all workers the expertise required for effective operation of their allocated stock picking carts. Accurate setup procedures combined with appropriate staff training directly contribute to achieving desired productivity levels using stock picking carts.

Optimizing Stock Placement and Layout for Stock Picking Carts

Source: net.au

Efficient inventory management starts with strategic placement. The careful arrangement of stock around the stock picking carts greatly impacts worker efficiency. Clear stock-picking locations, labels, and labeling system can drastically influence throughput of various orders using these invaluable stock picking carts. Employing proper methodologies ensures maximum performance by leveraging the mobility afforded by strategically designed stock picking carts.

Incorporating Technology with Stock Picking Carts

Incorporating technology further streamlines workflows associated with stock picking carts. Scanners, barcode systems, and potentially mobile computing are pivotal integrations, leading to enhanced accuracy, traceability and optimization of all picking and stock processes within your warehouse with efficient stock picking carts. Efficiently integrating stock picking carts and advanced inventory management technology elevates organizational capacity to execute higher order fulfillment.

Implementing Your Stock Picking Cart System

Scheduling and Work Allocation with Stock Picking Carts

A planned strategy for resource allocation ensures your staff understands roles and responsibilities surrounding stock picking carts. Careful consideration ensures proper staffing levels during busy periods, leading to optimized throughput and minimal inefficiencies with stock picking carts in various warehouse layouts. Well-structured processes associated with allocating stock picking carts for maximum efficiency optimize workflows while considering capacity to ensure each task can efficiently leverage stock picking carts.

Maintaining Stock Picking Carts for Longevity and Performance

Regular maintenance, adherence to the manufacturer's guidelines and consistent stock picking cart inspections guarantee long-term usability of this pivotal component. Proactive measures promote the lasting integrity of the inventory process via maintained and appropriately-cared-for stock picking carts. Ensuring ongoing high-performance functionality and stability over extended periods are significant advantages provided through proper maintenance protocols for your stock picking carts.

Analyzing and Optimizing Performance of Stock Picking Carts

Continuous assessment and evaluation using key metrics ensure continuous enhancement of operations via adaptable stock picking carts. Tracking data collected regarding picking times and inaccuracies assists in recognizing improvement opportunities and adapting picking carts to achieve peak effectiveness. Analyzing your system's productivity data allows adjustments to the deployment of your stock picking carts, optimizing overall effectiveness of picking and packing. Data analysis regarding productivity from employing stock picking carts contributes substantially towards long-term gains.

Future Trends in Stock Picking Carts

Autonomous Stock Picking Carts: The Future of Warehouse Automation

Future iterations involve advanced automation like self-driving or autonomous stock picking carts, transforming warehouses. This integration of advanced technology promises greater efficiencies for your warehouse and can dramatically change workflows, introducing automation and intelligent software solutions for high-efficiency stock picking cart operations.

Source: rackcdn.com

AI-Powered Stock Picking Carts

Integration with AI will bring enhanced levels of precision, prediction, and process optimization, adjusting to variability with superior stock picking carts. Advancements will improve existing stock picking cart methods and enhance inventory processes significantly with future developments, creating a paradigm shift within stock picking operations and creating more capable stock picking carts.

These considerations and a methodical, phased rollout, leveraging modern techniques and new technology can create a comprehensive strategy for the successful deployment of high-performance stock picking carts, which form an integral part of a contemporary logistics environment. Ultimately, optimizing your use of stock picking carts empowers warehouses to maintain their competitive advantage and streamline overall operations for optimized processes.