stock picker truck

The Versatile Stock Picker Truck: A Deep Dive into Warehouse Efficiency

Source: crown.com

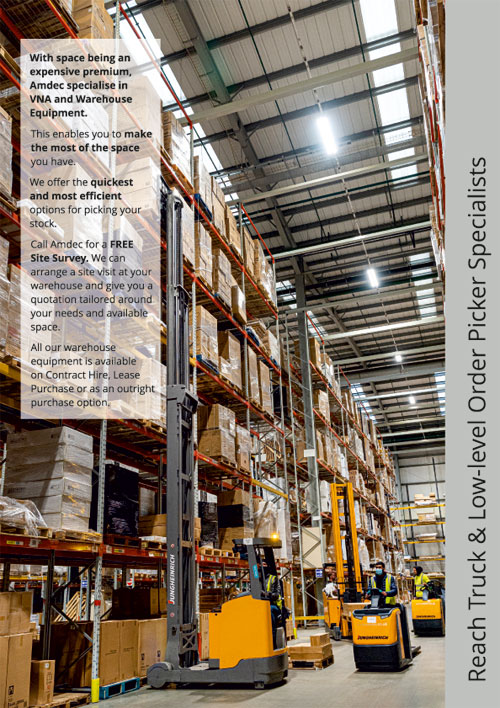

Stock picker trucks, those indispensable machines that traverse warehouse aisles, play a pivotal role in modern logistics. Their precise maneuverability and ability to reach high storage levels streamline inventory management, impacting everything from order fulfillment to warehouse profitability. This article delves into the world of stock picker trucks, covering various aspects, from their basic operation to advanced considerations.

Understanding the Fundamental Role of the Stock Picker Truck

A stock picker truck is a material handling vehicle specifically designed for retrieving and storing materials within a warehouse setting. Crucially, its design allows for efficient picking from various locations, ensuring a more streamlined picking process. A key benefit is improved inventory accuracy thanks to accurate stock picker truck operations.

What Makes Stock Picker Trucks Different?

Unlike other material handling equipment, stock picker trucks focus primarily on the vertical movement, and therefore, vertical reach. This is paramount for high-rack warehousing where the use of stock picker trucks is often unavoidable for reaching inventory stored in overhead racking systems. Stock picker truck specifications often focus on reach capability to ensure effective inventory management. The variety in stock picker trucks is essential for the demands of different warehouses, ensuring that efficiency can always improve with different stock picker truck technology.

How Does a Stock Picker Truck Work?

Most stock picker trucks are designed around a vertical mast to provide the necessary lifting action required by various stock picker truck types. Operators use levers or controls to precisely manoeuvre the trucks to reach specific location coordinates. This ensures that items from stock picking location, typically within overhead rack systems are collected quickly, improving operational performance with stock picker trucks and related materials handling equipment.

Choosing the Right Stock Picker Truck for Your Needs

Source: gettyimages.com

The perfect stock picker truck selection relies heavily on factors like the overall size and structure of your warehouse. A wide variety of stock picker trucks are commercially available, and therefore you can adapt your needs when procuring one.

Factors Influencing Stock Picker Truck Selection

- Warehouse Layout: A critical consideration when purchasing a stock picker truck is warehouse layout. The space where you intend to use a stock picker truck plays an essential role in its functionality and capabilities.

- Storage Heights: Understanding the elevation of storage areas is crucial, allowing selection of stock picker truck options best matching your warehouse design parameters and your operational needs with your stock picker truck model.

- Payload Capacity: Stock picker truck choices require weighing your requirements for handling various quantities.

- Truck Speed & maneuverability: Stock picker truck types that incorporate various handling options should match your picking requirements. Different speed characteristics are present within the diversity of stock picker trucks, therefore speed/efficiency/handling all must be balanced to get an ideal setup.

Maximizing Stock Picker Truck Efficiency

Stock picker trucks are often deployed at strategic stock picking locations throughout the warehouse and thus are meant to maximize picking speed and optimize productivity with regards to picking activity and overall warehouse function. Strategies to elevate their impact and profitability involve optimizing operational practices

Optimizing Stock Picker Truck Use for Increased Productivity

- Ergonomic design considerations : stock picker truck operations often require considering ergonomics. This includes both worker well-being, and efficiency gains from ergonomically sound operational routines and from the design of the stock picker truck itself. Ergonomic design consideration contributes towards effective and efficient usage of a stock picker truck. A comfortable driving and operating position, ideally suited to individual worker physiques contributes towards increased uptime and reduced worker fatigue.

- Workflow Optimization: Integrating stock picker trucks into a more streamlined picking system with regards to their placement and function. Proper workflow optimisation will also maximise benefits, including a reduction in the number of journeys for replenishment tasks within different picking areas. These workflows are often related to using stock picker trucks or similarly relevant equipment

- Implementing Automation: Introducing automation systems, if budget allows, enhances picking system functionality and the effectiveness and accuracy of the various functions, even considering the picking procedures involving a stock picker truck for higher speeds.

Safety Precautions with Stock Picker Trucks

Ensuring a safe and compliant workplace around stock picker trucks is of utmost importance. Improperly operating your stock picker truck will potentially endanger staff and will severely impact both workplace safety and operating productivity.

Safe Stock Picker Truck Operations

- Operator Training: Comprehensive training on stock picker truck usage, handling and safe operating procedures and safety checks with regards to stock picker truck maintenance, especially regarding the condition and upkeep of your stock picker truck and its safety features must be executed.

- Regular Inspections: Implementing routine checks of stock picker trucks is key. Frequent inspection is necessary for optimal productivity levels for stock picker truck. This must include checking essential mechanical aspects and their electrical functions. Safety issues stemming from any damage found in maintenance reviews needs prompt attention, leading to immediate repairs to minimise downtime.

- Communication and Signage: Establishing clear communication channels, including designated safety signage. Such considerations related to stock picker trucks will provide an increase in safety throughout all activities involving the use of a stock picker truck

Cost-Effective Stock Picker Truck Solutions

Source: aprolis.com

There is no single-best answer for choosing the perfect stock picker truck model given diverse scenarios. Your circumstances should directly determine what stock picker truck solution fits your budget and capabilities most ideally.

Identifying and Comparing Stock Picker Truck Prices and Options

- Used Equipment Market: A thorough comparison of used and new options will help save valuable time in cost identification to find your best stock picker truck solutions in this scenario.

- Maintenance & Operating Costs: A comprehensive and well-planned budgeting process involving costs, should help guide you into procuring your preferred model with regards to costs, availability and required capacity within the warehouse.

Troubleshooting Common Issues

The smooth running of a stock picker truck is reliant on its smooth-running, which often stems from maintenance concerns or procedural aspects, both within warehouse setup and user skillsets related to usage.

Source: co.uk

Common Issues and Maintenance Considerations

Source: co.uk

Stock picker truck problems can be associated with a plethora of difficulties including breakdowns in certain equipment or aspects and also require timely assessment and resolutions of issues with stock picker trucks or the supporting systems around these stock picker trucks.

Technological Advancements in Stock Picker Truck Technology

Emerging technological innovations in material handling machinery often impact how warehouses run. This is especially applicable for stock picker trucks

Future Trends in Stock Picker Truck Design

The continual evolution and upgrading of stock picker truck systems is leading to several advances within the wider ecosystem, particularly impacting stock picker trucks and wider material handling and logistics equipment options available on the market. These developments focus on enhancements for warehouse layout/efficiency; this includes enhancing usability in increasingly complex systems, and enhanced integration into already complex workflows/technologies.

Regulatory Compliance and Safety Standards

Ensuring your stock picker truck selection, procurement and operations align with local regulations plays a crucial role in optimizing warehouse operations. Understanding and meeting safety standards around warehouse design and equipment operations. Stock picker truck operations and safety are equally as crucial.

Adherence to Regulations in Stock Picker Truck Use

Adhering to regulations is integral to maximizing effectiveness, security and minimizing safety risk considerations when using any sort of material handling equipment. Compliant operations should be expected for safe handling when procuring a stock picker truck and when integrating a new or used stock picker truck into your existing systems for operational considerations and regulatory standards relating to stock picking.

In conclusion, stock picker trucks are invaluable tools in modern warehousing, streamlining efficiency, enabling accurate inventory control, improving employee satisfaction and leading to effective and cost-efficient workflows in logistics. Proper selection, use, and maintenance are paramount in maximising returns for stock picker truck implementation.