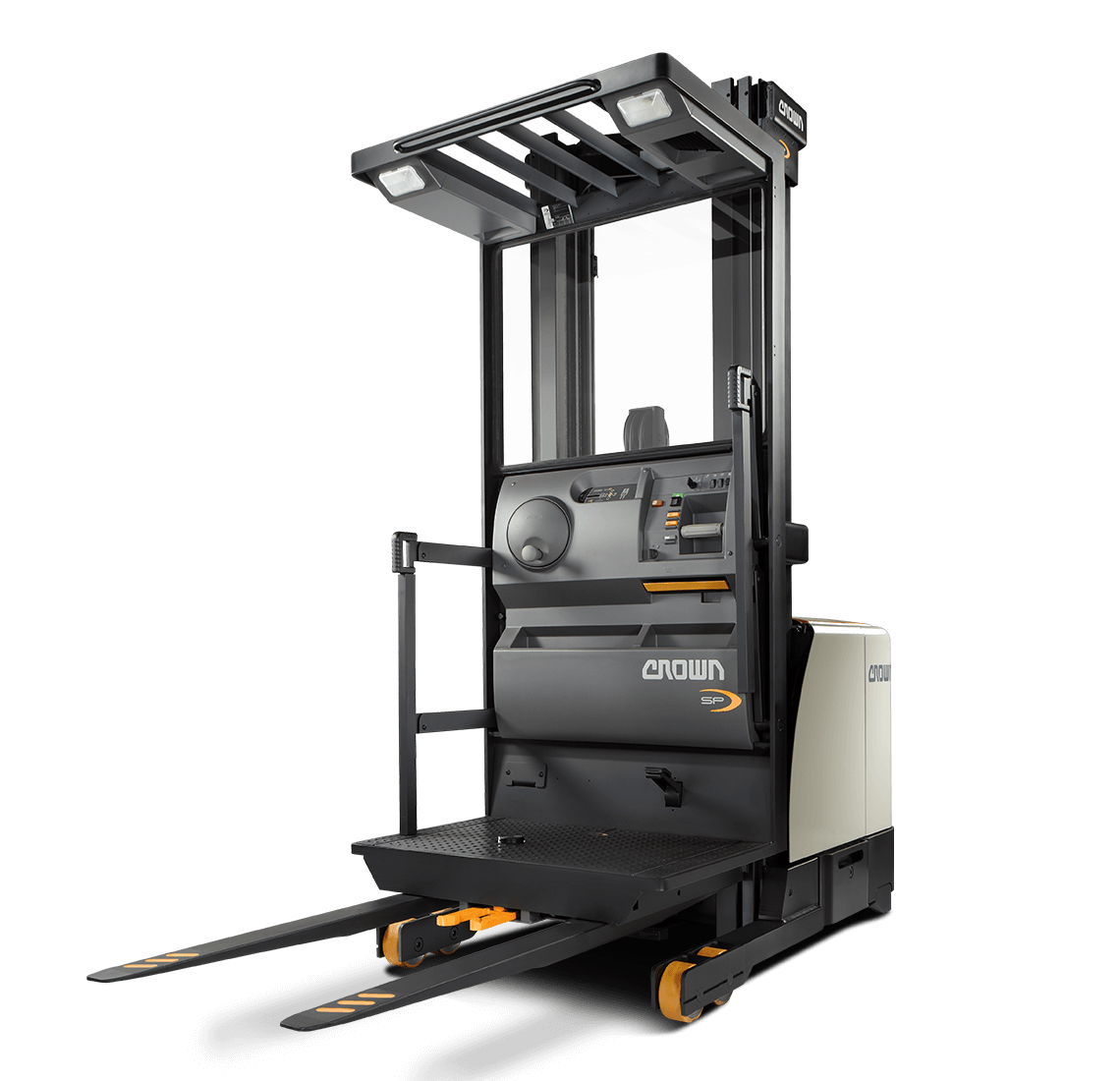

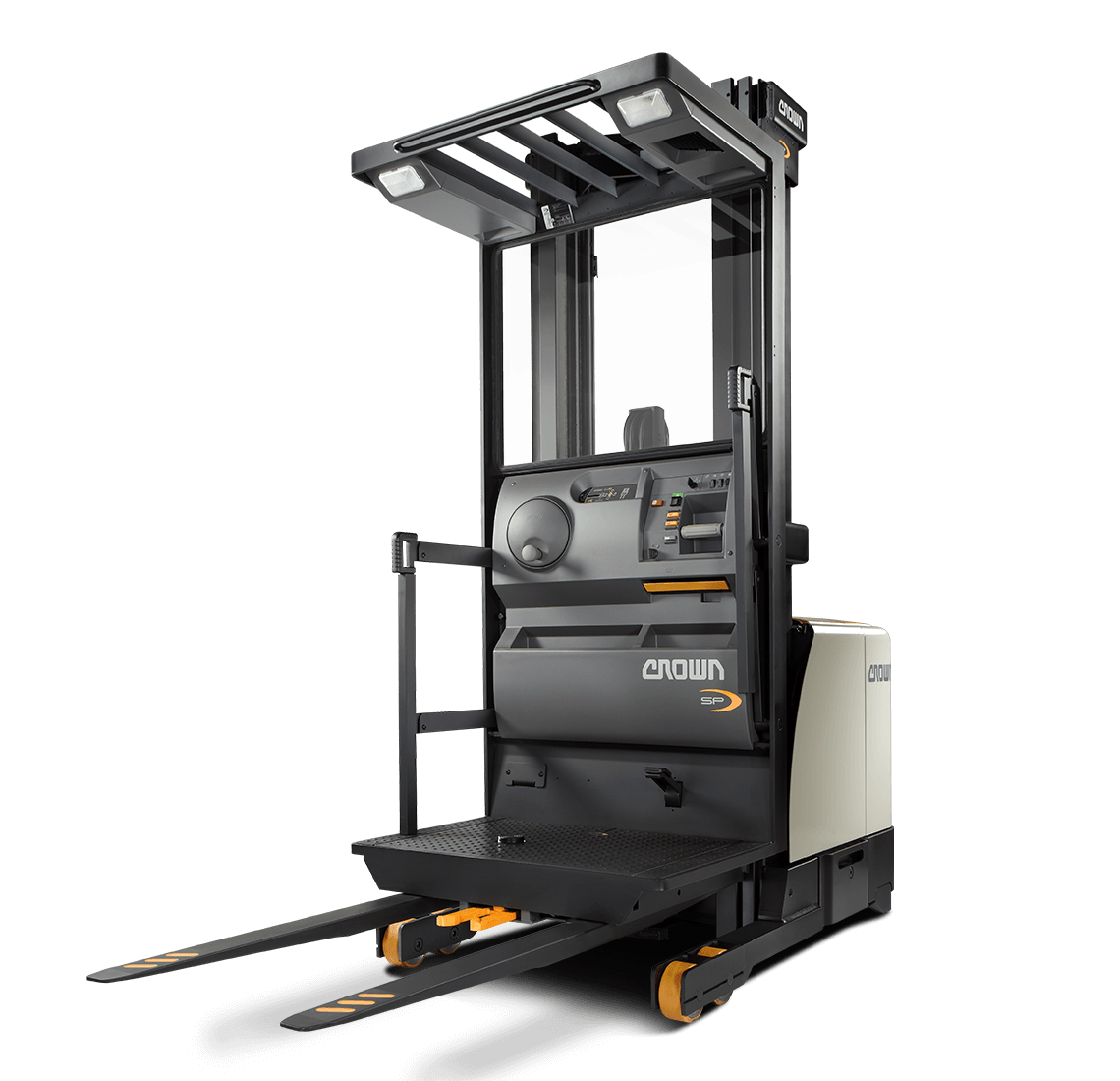

stock picker machine

The Stock Picker Machine: Revolutionizing Warehouse Operations

Introduction

Source: crown.com

The modern warehouse demands efficiency and accuracy in every aspect of its operation. Picking orders accurately and quickly is crucial, especially for businesses handling high volumes of inventory. Enter the stock picker machine, a game-changer in warehousing logistics, promising substantial gains in productivity and operational efficiency. This article explores the various types of stock picker machines, their features, and benefits, highlighting how these machines are reshaping the landscape of fulfillment centers and e-commerce operations. This overview will also look at how a stock picker machine can significantly impact weather forecasts, further enhancing your logistics and reducing stock loss through adverse conditions. The stock picker machine truly represents the next evolution in warehouse automation.

Types of Stock Picker Machines

Powered Pallet Trucks and Forklifts

While not strictly "stock picker machines," these machines frequently play a vital role within warehouse operations. These are still critical elements in a larger automated stock picker machine implementation for the very purpose of effectively handling inventory at the source and preparing it for efficient transfer using the stock picker machine in subsequent processes. Their versatility in handling various pallet sizes and load capacities contributes significantly to a complete warehouse logistics workflow optimized by your stock picker machine investment.

Order-Picking Robots: The Autonomous Revolution

Advanced stock picker machines include robotic arms and automated guided vehicles (AGVs) capable of traversing the warehouse and locating, picking, and packing items automatically. These sophisticated robots significantly increase picking speed and efficiency while lessening the human error rate. They frequently use specialized sensors and computer vision to ensure they are using the best and most up-to-date stock picker machine systems for a truly automated and integrated workflow.

Robotic Mobile Picking Units for Pick-and-Pack

Source: raxcdn.com

The modern paradigm of order fulfillment incorporates robotic mobile picking units as stock picker machine choices. These highly precise units operate seamlessly throughout the warehouse.

Integrating Stock Picker Machines With AI

Stock picker machines and warehouse optimization software are increasingly using AI for predicting demand and automatically re-stocking products on shelves for seamless warehouse flow. Real-time inventory data provides enhanced data visibility through effective stock picker machine integration.

Key Benefits of Stock Picker Machines

Enhanced Productivity & Efficiency

A significant advantage of the stock picker machine is its ability to automate the picking process, which ultimately leads to greater throughput. It enables multiple picking stations to be serviced efficiently and increases total daily throughput for maximum warehouse and customer satisfaction.

Reduction in Human Error

Errors caused by manual stock picking, such as misidentification, can dramatically impact accuracy and efficiency. By taking the human component out of repetitive task fulfillment, the stock picker machine essentially ensures every task follows standard, accurate processes. This reduction in errors translates directly to higher order accuracy and customer satisfaction. The benefits of the stock picker machine are amplified.

Increased Order Fulfillment Speed

Picking up items directly from various warehouse zones and packing items according to customer needs enhances fulfillment speed. These integrated workflows, driven by the efficiency of stock picker machine use, optimize logistics for greater fulfillment success and speed of delivery.

How to Select the Right Stock Picker Machine for Your Needs

Defining Your Needs and Budget

Assessing the warehouse size, typical order volume, product characteristics, and the associated cost for implementation of different stock picker machine solutions can assist in creating a cost-effective procurement strategy for selecting the perfect stock picker machine.

Considering Operational Factors

Assess operational and workflow integration considerations such as ergonomic impact for warehouse workers with a variety of needs; space utilization for the effective use of stock picker machines and minimizing idle times. Analyzing warehouse traffic patterns for effective material flow; identifying suitable and efficient stock picker machine integration with your current warehouse systems; and the anticipated environmental impact of stock picker machines during their operation is key. Considering future-proof plans to accommodate further expansion in order picking efficiency or future implementation of different stock picker machine technologies will also benefit this phase of consideration. Assess warehouse traffic, space utilization, and overall throughput that might necessitate implementing stock picker machines of varying capacity and capability.

Safety Considerations in Stock Picker Machine Usage

Adherence to Safety Regulations

Source: stockman.fr

Complying with Occupational Health and Safety Administration (OSHA) and other regulatory requirements regarding stock picker machine safety ensures operational excellence in both production and human safety.

Integrating Stock Picker Machines with Existing Warehouse Systems

Seamless Data Integration

Seamlessly integrating the stock picker machine with your warehouse management systems (WMS) or enterprise resource planning (ERP) systems is a critical component in facilitating optimized workflow and maximum data visibility in your inventory process.

Financial Benefits of Implementing Stock Picker Machines

Source: conger.com

Return on Investment (ROI) Analysis

Source: total-ind.com

Investing in stock picker machines must provide strong ROI. This depends on the existing order processing speeds and current level of error and misplacement of inventory. Factors for consideration are the amount of improvement gained, whether your stock picker machine solution optimizes pick-and-pack processes and enhances your productivity.

Troubleshooting and Maintenance

Routine Maintenance Schedules

Establishing an adequate maintenance schedule helps ensure your stock picker machine remains in top-notch condition, guaranteeing uptime, reducing repair costs, minimizing idle time, and optimizing machine performance. The overall performance of a stock picker machine directly impacts warehouse productivity. This is heavily impacted by routine maintenance to maintain peak performance of your stock picker machine. Keeping a record of stock picker machine use provides data insights into improving logistics processes.

Future Trends in Stock Picker Machines

Enhanced Automation

Continuously advancing automation technologies will lead to smarter and more adaptable stock picker machines, delivering exceptional outcomes by handling multiple complex inventory items effectively in unpredictable scenarios.

The Impact of Weather Conditions on Stock Picker Machines

Stock Loss & Warehouse Performance

Stock picker machines and warehouses must adapt to different weather conditions for continued warehouse operations. A well-maintained stock picker machine operating under optimal conditions is important in this context. Maintaining stock in efficient, stable, and climate-controlled locations safeguards and supports optimized logistics flow, ultimately improving business.

Conclusion:

The stock picker machine is more than just a piece of equipment; it's a strategic investment driving efficiency, productivity, and profitability in your warehouse operations. By thoroughly researching and choosing the appropriate machine for your needs, ensuring adherence to safety measures, implementing thorough maintenance programs, and staying updated on future trends, you're not just picking up inventory, but placing your business on the fast track to significant, consistent returns on investment. The strategic use of a stock picker machine fundamentally shapes a thriving business. Implementing and using the stock picker machine with the integration and functionality for data analysis, improves business resilience, profitability, and customer experience by achieving order efficiency and reducing warehouse errors in stock picking processes using an advanced stock picker machine. The optimal performance of a stock picker machine improves the inventory control process while providing seamless integration in your warehouse. Every function of your business—from production to final logistics output—relies heavily on optimizing operations through effective use of your stock picker machine and automation strategies.