pick/stock quantity in sales units

Optimizing Pick/Stock Quantity in Sales Units: A Comprehensive Guide

This article delves into the critical aspect of managing pick/stock quantity in sales units. Understanding how to accurately calculate and manage these figures is crucial for efficient operations, cost control, and overall profitability in any business handling goods. Accurately forecasting and controlling your pick/stock quantity in sales units directly impacts your inventory management. Proper handling leads to better cash flow and efficient use of resources. We will cover key areas from initial planning to ongoing optimization to help your team effectively manage pick/stock quantity in sales units.

Understanding the Importance of Pick/Stock Quantity in Sales Units

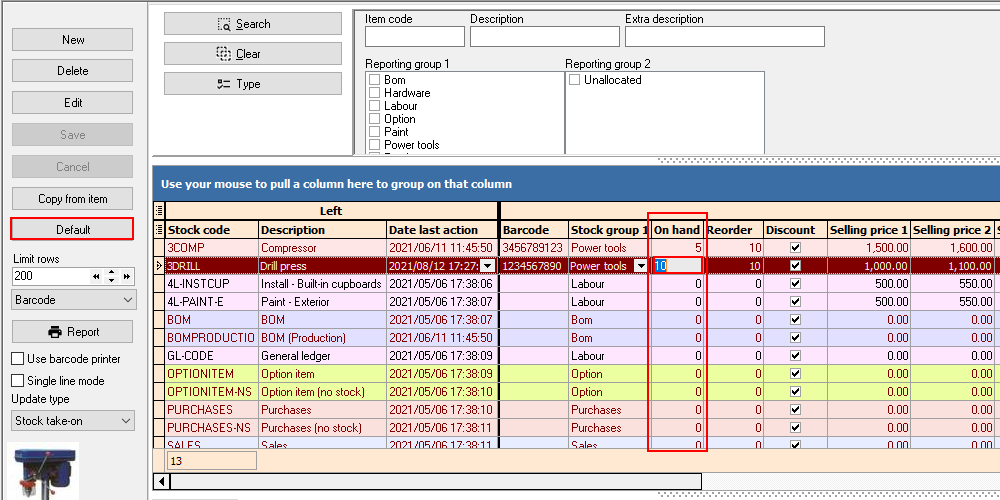

Source: turbocash.net

Accurately determining the optimal pick/stock quantity in sales units is not just a technical exercise. It has real-world consequences for your entire operation. A high quantity of inventory ties up capital and exposes your company to potential storage costs and spoilage (if applicable). Conversely, a low pick/stock quantity in sales units could lead to stock-outs and lost sales. Ensuring the right pick/stock quantity in sales units supports a reliable fulfillment process, boosting customer satisfaction. The appropriate pick/stock quantity in sales units directly relates to satisfying customer demands while also keeping holding costs to a minimum.

What Exactly is "Pick/Stock Quantity in Sales Units"?

This term refers to the number of items of a given product that you need to have in stock and available for picking to fulfil orders, expressed in sales units, not physical units. The focus is on the expected number of orders to fulfill. Knowing the pick/stock quantity in sales units is vital for calculating reorder points, preventing shortages, and optimizing warehousing space utilization.

How to Accurately Forecast Pick/Stock Quantity in Sales Units

Precise prediction of future sales is the foundation for correct pick/stock quantity in sales units.

Historical Data Analysis and Trend Identification

Examining historical sales data to identify trends and seasonal fluctuations is essential for predicting future demand. Accurately analyzing the pick/stock quantity in sales units over time can reveal crucial insights for proactive inventory management. Thorough data analysis about past pick/stock quantity in sales units allows you to extrapolate reasonable expectations for the future.

Understanding Seasonal Variations

Sales patterns can differ drastically across seasons. Understanding seasonal variations for your products is vital. High fluctuations necessitate adjusting the pick/stock quantity in sales units proactively for peak and low demand. Analyze historical data and tailor the pick/stock quantity in sales units to seasonal sales surges to avoid shortages during peak seasons and excess inventory during low seasons. A solid forecast using past data and seasonality trends greatly assists you to efficiently manage the pick/stock quantity in sales units.

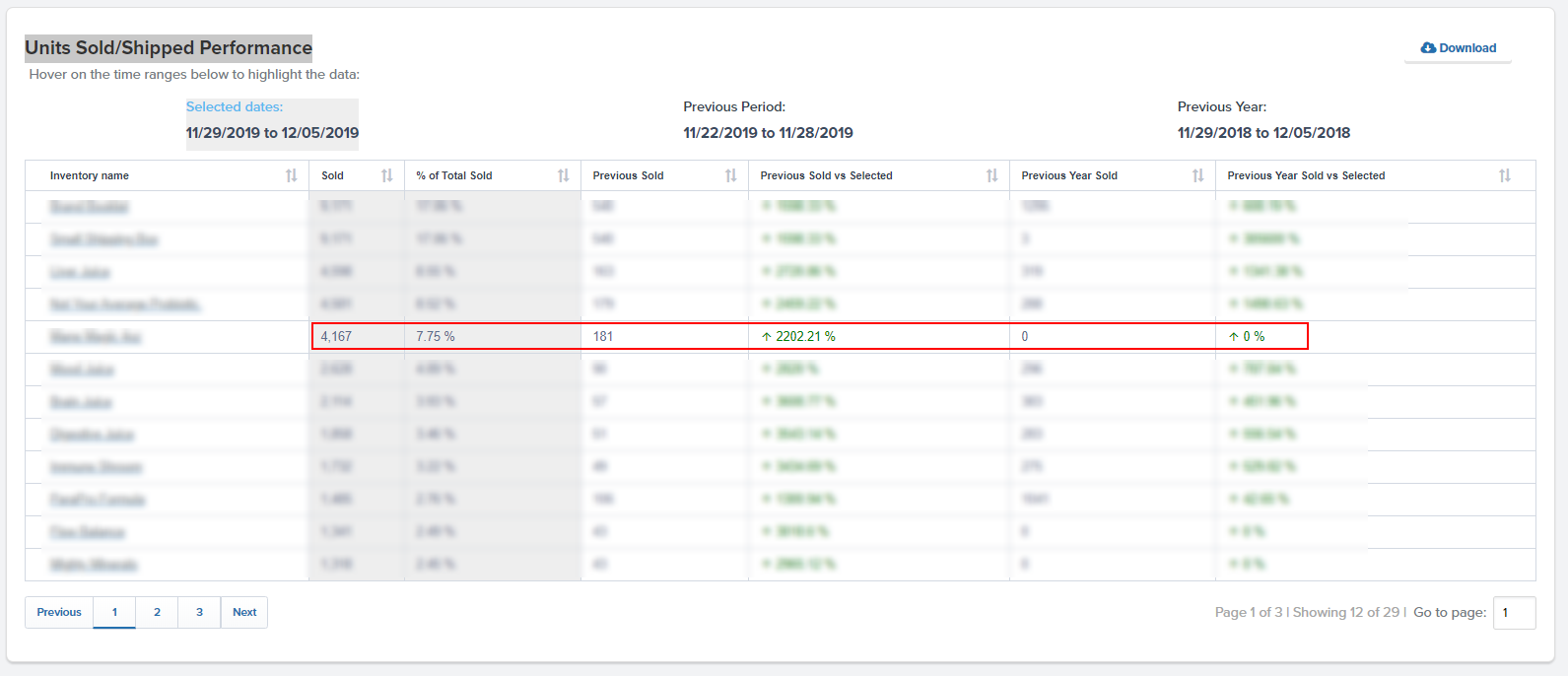

Utilizing Sales Projections and Demand Planning Tools

Utilize accurate sales projections to calculate the anticipated future pick/stock quantity in sales units for each product line. The tools available are important aids in the pick/stock quantity in sales units forecasting process. Some helpful demand planning tools, including sales forecasting software, allow you to project the necessary quantities with high accuracy, guaranteeing sufficient quantities for a streamlined pick/stock operation using your data accurately.

Determining Optimal Stock Levels with Safety Stock

Understanding how to handle safety stock is fundamental to optimal pick/stock quantity in sales units. Safety stock is an added layer to address fluctuations and variability in the pick/stock quantity in sales units, which might result from unpredictable events. Calculating optimal pick/stock quantity in sales units is a crucial process that considers multiple factors.

Source: shipbob.com

Identifying the Causes of Demand Fluctuations

The fluctuation in sales impacts the need for extra inventory, also known as safety stock. Determining the reasons for the demand variations is key to defining a reliable pick/stock quantity in sales units that absorbs any disruption to supply and demand. Pick/stock quantity in sales units is affected by numerous external forces beyond the control of an organization, and having buffer stock in place ensures operational continuity.

Calculating Safety Stock Levels Based on Historical Data

Statistical methods allow a nuanced understanding of fluctuations and variation to ensure adequate safety stock to deal with any supply disruptions or demand changes. Using the past history to model these conditions is vital when calculating and analyzing your pick/stock quantity in sales units and how it's impacted by factors.

Optimizing the Pick/Stock Process in Sales Units

Strategies that work well in ensuring consistent pick/stock quantity in sales units is beneficial.

Inventory Management Systems (IMS)

Source: cdnwm.com

A well-implemented IMS assists immensely in optimizing your inventory management by providing real-time information about pick/stock quantity in sales units across different locations. Your software or systems support the pick/stock quantity in sales units calculation for real-time analysis and accuracy. These systems help forecast pick/stock quantity in sales units, calculate reorder points, and track stock levels across all your warehouses. An efficient inventory management system reduces issues like out-of-stock situations and allows a company to correctly implement the optimal pick/stock quantity in sales units to run the operations with precision and speed.

Implementing First-In, First-Out (FIFO)

FIFO management of goods directly influences pick/stock quantity in sales units, as the oldest goods get prioritized during picking. It improves quality and ensures older items are sold first and fresh product gets stocked correctly for the anticipated demand to ensure a good process for the pick/stock quantity in sales units, reducing storage costs.

Source: stoneridgesoftware.com

Implementing Quality Control During the Pick Process

Maintaining standards during the picking process guarantees that each item matches orders accurately. Consistent pick processes enhance customer satisfaction, and maintaining product consistency also directly relates to correct pick/stock quantity in sales units management and tracking and thus keeps all units intact, from start to end, including their pick/stock quantity in sales units.

Maintaining Real-Time Inventory Data Updates

Maintaining accurate real-time data on inventory is essential for correctly applying your pick/stock quantity in sales units calculations and ensuring the correct quantities are available at all times. Data errors can seriously harm decision-making.

Utilizing Tracking Technologies and Software

Real-time tracking through various technologies allows up-to-date knowledge of item locations and stock quantities. Implementing barcode or RFID scanners enables immediate feedback, assuring that actual quantities and inventory balances line up with the target pick/stock quantity in sales units for all your operations, to guarantee effective decision making on demand. The stock levels' real-time monitoring gives reliable support when managing the pick/stock quantity in sales units, as well.

Periodic Inventory Audits and Reporting

Performing periodic inventory audits provides comprehensive validation and supports the ongoing effort in maintaining accuracy with real-time, operational, correct pick/stock quantity in sales units that is essential for forecasting the requirements, planning adequately, and monitoring inventory properly for all areas and activities. Data accuracy in reports maintains the value and reliability of your systems to keep the business efficient.

Conclusion: Adaptability in Inventory Management

Adapting your strategies for managing pick/stock quantity in sales units remains crucial as market conditions evolve. Forecasting must always factor in economic trends, shifts in consumer behavior, and other external changes, thus requiring adjustments to accurately calculate the necessary quantities. Having accurate data ensures informed inventory decisions based on true data related to pick/stock quantity in sales units to continue optimizing the process. Adaptability allows for flexibility, which means businesses must react in a rapid manner in response to change. Continual adaptation to changing environments remains essential for businesses and is central to their pick/stock quantity in sales units to improve profitability and accuracy for future inventory planning and forecasting. This ongoing effort allows businesses to plan, anticipate, and fulfill order requirements promptly for excellent business continuity. Proactive changes for better, more effective stock-related data in pick/stock quantity in sales units leads to long-term, reliable, consistent results. Finally, it is critical to ensure the proper analysis of your inventory pick/stock quantity in sales units to determine how adjustments impact each department and section in your operational setup. This crucial step helps provide efficiency and continuity throughout.