order picker harness requirements

Order Picker Harness Requirements: A Comprehensive Guide

Source: associated-solutions.com

Order picking is a critical component of many warehousing and logistics operations. Safe and effective order picking relies heavily on the appropriate and correctly used order picker harness requirements. This article delves into the essential aspects of order picker harness requirements, ensuring optimal safety and productivity.

Understanding the Importance of Order Picker Harness Requirements

Order picker harness requirements are more than just a safety feature; they are a fundamental necessity for minimizing injuries and maintaining a safe working environment in warehouse settings. Properly designed and utilized order picker harnesses can prevent serious falls and injuries that can result from slips, trips, or accidental impacts when operating an order picker. A thorough understanding of order picker harness requirements is crucial for maintaining workplace safety standards.

Types of Order Picker Harnesses and Their Functionality

Source: certifymeonline.net

Source: wixstatic.com

Order picker harnesses come in various designs. Understanding the nuances of these different models is paramount in adhering to order picker harness requirements. Certain harnesses might be specialized for specific order picking tasks or applications. Choosing the correct model based on individual warehouse needs and operator characteristics is a key aspect of order picker harness requirements. Each style comes with inherent order picker harness requirements in terms of its components.

Choosing the Right Harness: A Practical How-To

This section provides practical instructions for determining the most appropriate order picker harness based on your specific situation. How can you ensure your choice of order picker harness adheres to order picker harness requirements? Start with:

- Analyzing your warehouse environment: Consider the specific hazards present, such as uneven surfaces, heavy equipment, and overhead obstructions. Understanding order picker harness requirements demands a clear grasp of the conditions in which these tools operate.

- Identifying the task demands: What tasks do the operators perform regularly with the order picker? Specific order picker harness requirements might arise depending on the frequency of lift operations, elevated heights, and potential impacts during use. The choice of harness impacts how a warehouse or other operation aligns with order picker harness requirements.

- Consulting safety regulations: Check national and local regulations, as many jurisdictions have stringent order picker harness requirements and standards, some including the European standards concerning safety. Referencing industry best practices helps one understand order picker harness requirements from various standpoints. There are stringent order picker harness requirements even regarding material safety and compatibility in some contexts.

Key Features and Specifications in Order Picker Harness Requirements

Understanding crucial order picker harness specifications is essential for safety and proper function. Several features consistently appear in good order picker harness requirements.

- Harness material: Durability, breathability, and comfort influence safety. High-quality, long-lasting materials form the base of proper order picker harness requirements.

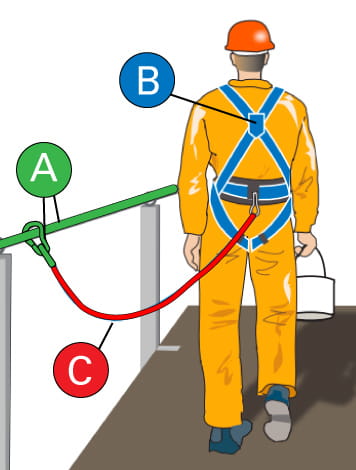

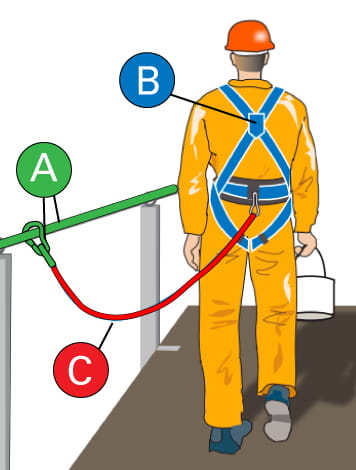

- Attachment points: Safe, secure anchor points on the harness are critical for order picker harness requirements. Correct placement and function, according to manufacturer standards, for specific harnesses, is a direct factor in achieving proper order picker harness requirements.

- Adjustability: Individualized fit minimizes risks from unexpected movement, essential aspects of order picker harness requirements and best practice standards.

- Certification and standards compliance: Thorough checks of appropriate order picker harness requirements and adherence to the necessary certifications and industry standards help provide assurance for a suitable and approved harness.

Maintaining Proper Order Picker Harness Fit and Functioning

Regular maintenance and proper handling of the order picker harness ensures continuous safe operations and reduces any risks relating to failure of order picker harness requirements. Proper care also increases safety measures across order picking operation tasks.

How-To for Inspecting and Maintaining an Order Picker Harness

Order picker harness requirements demand that inspections occur periodically.

- Regular visual inspections: Look for any wear and tear or damage to the webbing, stitching, buckles, or other components. Note any significant discrepancies between order picker harness requirements and existing order picker harness practices or policies.

- Thorough functional checks: Check if all fittings and fastening mechanisms are functional. Ensure no loose or damaged components impede appropriate functionality under order picker harness requirements.

- Periodic maintenance procedures: If order picker harness requirements dictate special maintenance, ensure the appropriate care and checks for maintenance, using a schedule and procedure checklist and instruction documentation on the procedures that align with order picker harness requirements and with professional or best practices.

- Compliance with safety regulations and industry standards: Regular check and verification on adherence and compliance with pertinent industry and national or local safety and relevant standards on order picker harness requirements.

Order Picker Harness Usage Procedures: Essential Guidance for Users

Source: warehousedesign.net

Order picker harness requirements extend beyond just purchase and inspection. Proper usage procedures ensure sustained efficacy and mitigate order picking risk.

- Training and instruction: Detailed instruction for each member performing the role and for each different type of equipment is critical for compliance with order picker harness requirements and standards, minimizing hazards and increasing user awareness of order picker harness requirements and best practices in the workplace.

- Personal fit checks: Operators need to make sure the harness fits properly before using it in any order picking operation or related procedure that requires or is aligned with order picker harness requirements. Ensure that any order picker harness that has had adjustments made can continue to be checked for functionality under order picker harness requirements.

- Proper positioning: Alignment and fitting, correctly aligned in relation to the task performed and the individual worker in operation, is one essential aspect of order picker harness requirements.

Emergency Procedures Related to Order Picker Harness

Understanding what to do in the event of a malfunction of equipment (and order picker harness in particular) or potential issue related to the functioning of the order picker harness system, as it aligns to order picker harness requirements, helps maximize response time and minimize risk or damage if any problems arise, which is aligned with any safety and or efficiency considerations that also arise as order picker harness requirements evolve.

Importance of Proper Anchoring of Order Picker Harnesses

Secure anchoring aligns directly with ensuring worker safety. The quality of order picker harness anchorage relates significantly to its operational safety features. Improper anchorage fundamentally violates critical order picker harness requirements and undermines its purpose, as well as best practices.

Evaluating and Improving Order Picker Harness Program

Source: cloudfront.net

A constant evaluation is crucial. This regular check in conjunction with any appropriate industry regulations and standards enables businesses to ascertain alignment of current and evolving procedures, techniques, and order picker harness requirements in order picking to meet current practices or regulations. Continuous evaluation of an existing program aligns effectively to order picker harness requirements and contributes significantly to the effectiveness of risk mitigation practices.